There are a number of different methods of classifying counterfeit coin types. One is based on the material used in the counterfeit. Another used for struck one-pound counterfeits by D.J.Cane, note 1, is based on the type of edge lettering found on the counterfeit one-pound coin. The system preferred by this author bases a primary classification on the method of transferring the image onto the counterfeit coin, note 2. The primary classes can then be sub-divided according to material classes and/or physical characteristics. There are five primary classes in this system at present.

1.0 Cast counterfeits

This class includes metal alloys solidified in a mould containing the coin design. It also includes any other technique where a liquid is solidified in a mould, for example an acrylic resin.

This method of producing a counterfeit coin is probably one of the oldest known. Traditionally it consists of producing a mould usually made using a genuine coin as a template. Molten metal is then poured into the mould and the metal allowed to solidify. Done well, this produces a very good copy of the original coin, including any defects present on the original. Carried out poorly, it produces a very unconvincing copy. In the small castings industry, vacuum and centrifugal casting have mostly replaced gravity feeding of the molten metal into the mould. The suspicion is that the higher volume producers of this type of counterfeit may be using these techniques.

Most of the cast, one-pound counterfeit coins found have been produced from low melting point white metal alloys. These alloys are usually based on metals such as lead, tin, antimony or more unusually bismuth. The alloys melt between 200 to 350 degrees centigrade. This range of temperature can be achieved using a conventional natural gas burner. The actual alloy mixture used is important as many of these alloys shrinks during solidification. These alloys are usually grey or silvery and require to be coated to imitate the pale yellow one-pound coin.

Up to 1995-96 the cast white metal counterfeit was the predominant one-pound counterfeit coin found in Britain. Other types in this class include brass casts and acrylic based counterfeits. The author has only seen a couple of acrylic counterfeits of the one-pound coin. An attempt had been made to increase the weight of the acrylic by mixing it with metal powder but the counterfeits were still much too light.

A photograph of coin P8, a one-pound counterfeit coin made from an acrylic compound and a metal powder

2.0 Struck counterfeits

The class includes use of a conventional coining press and the use of any other technique transferring the design from a master by means of pressure.

|

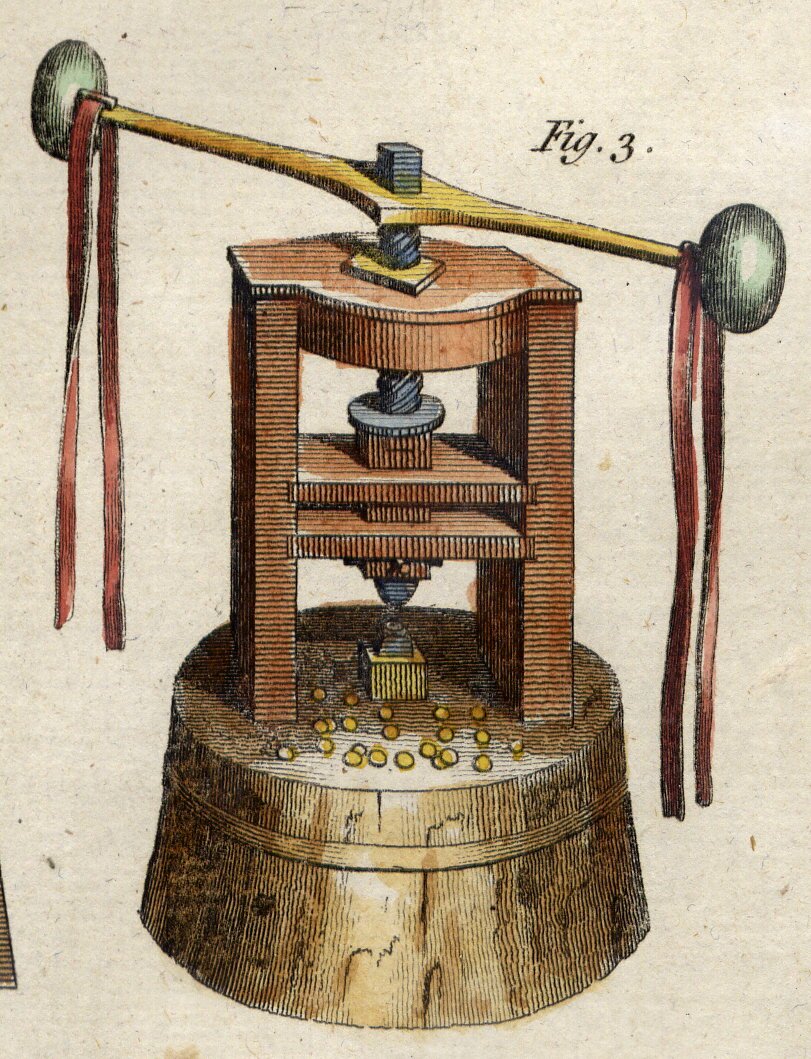

The conventional method of producing a coin is to strike a plain disc [blank] in between two harden steel dies. These dies transfer respectively the obverse and reverse images of the design onto the blank to produce the coin. The engraving to the left is reproduced from a plate from a late eighteenth century copy of Diderot's Encyclopaedia. Unfortunately it has been hand coloured in modern times. It shows a hand-operated screw press used to strike coins during this period. Such a press would require at least five men to operate. One man feeding the blanks in between the dies and four swinging the arms of the press. In the 1790's Boulton and Watt were the first to used steam powered coining presses. They produced the famous copper "Cartwheel" penny in Birmingham in 1797 using such presses. Lever presses were introduced in the nineteenth century. Today's high-speed presses can produce coins with up to 800 strikes a minute. Modern counterfeiters have shown as much ingenuity as press engineers in producing struck coins. They have used screw presses for collector coins but for circulating coins they often adapt hydraulic presses designed for other purposes. These usually operate relatively slowly. In the late 1990's one enterprising gentleman in London, bought a press, remarkably similar to a coining press, for "a couple of grand". It was bought from the classified advertisements in the British magazine, "Exchange and Mart". For some bizarre reason he attempted to use it to produce counterfeit fifty-pence coins rather than the higher value one-pound coins. He was caught before he could produce any counterfeits of a quality fit for use. |

Producing an image of the coin on to the coining die is one of the most difficult operations for the counterfeiter. This has been achieved by a number of processes, see note 3. The majority of struck one-pound counterfeit coins appeared to have been produced from dies copied by a spark erosion process. This consists of placing the image to be copied, usually a coin, along with a blank die into a dielectric fluid. A dielectric fluid is one that does not conduct electricity. A high voltage difference is caused between the two objects. This causes current to be transferred by means of sparks passing between the two objects. The sparks erode the die causing it to take on the design of the coin.

A spark eroded die has a very rough surface. Counterfeiters usually polish the flat areas such as the table to improve the appearance of any coins produced from the die. They find it difficult to polish the design and the vertical sides of letters etc. Under the microscope the roughness left by the counterfeiter can usually be seen on the counterfeit coin.

Enlarged image of genuine 1997 one-pound coin with no circulation damage

|

Enlarged image of a 1990 dated one-pound counterfeit "mule", coin P9. It was concluded to have been made from a spark erode die. Note: the flat tops to the letters and the rough sides and edges of the letters and beads. |

There were a very small number of struck binary brass one-pound counterfeit coins in circulation before 1990. However since about 1997 there have been a growing number of a characteristic struck brass alloy counterfeit in circulation. By 2002 it is the author estimation that this type of counterfeit constituted at least fifty percent and probably much more of the one-pound coin counterfeits in circulation. The author identifies this group of counterfeits as type NP. It would be plausible to conclude that the metal alloy for the type NP counterfeits originates from a single source, although it would appear that these counterfeits have been coined in more than one location. These type NP counterfeits appear to encompass a number of the differing edge letter types documented by D.J.Cane.

In March 2004 Ruth Kelly, then at the Treasury, stated that a second Royal Mint survey of "December 2003 indicated a counterfeit rate of just under 1% - almost identical to the previous years results". The Royal Mint estimated there were 1,410 million one-pound coins in circulation in December 2004. This would mean approximately 14 million counterfeit coins in circulation in 2004. If the author's estimate is correct then more than 7 million of these were type NP. For this group of counterfeiters this would probably mean a turnover of at least 4 to 6 million pounds from 1997 to 2003. More than half of this would be profit. Although these figures have a large margin of error they do show the large sums of money to be made in the low profile crime of coin counterfeiting.

3.0 Electrotype counterfeits

An electrotype is a relatively thin shell of electroplated metal which copies the contours of the electrode on to which it has been plated. The electrode is usually a plaster or rubber cast of the coin being counterfeited. This technique usually requires the electrotype to be filled or supported by another material.

The author is not aware of any electrotyped one-pound counterfeit coins. A few fifty-pence counterfeits of this type have been found.

4.0 One to one transfer counterfeits

This class includes counterfeits made with techniques such as the use of a pantograph or the direct use of spark erosion.

There have been no proven one-pound cointerfeit coins of this type. However there was an interesting group of brass counterfeits which were possibily of this type. This group surfaced in the late 1990's, the examples of these counterfeits seem by the author were all from the Midlands. It is easy to identify this type by its idiosyncratic edge lettering. This is:" DECUS LACESS TUTAMEN [no cross]". D.J.Cane, Note 1, classified this edge type as VII. It appears to have been an attempt by the counterfeiter to combine two types of edge lettering to enable it to be used with a number of different reverse designs.

Black and white photograph of coin P7, a type LA coin showing the characteristic machining marks. More detailed coloured images can be found on the counterfeit example pages. |

The author has identified this group of counterfeits as type LA. Apart from their edges they are characterised by circular turning marks on the coin face. They have deeper circular marks at the coin centre, similar to centering marks sometimes found with items turned by a lathe. A metallurgical examination of a coin of this type showed a cast crystal structure with a small amount of distortion of this crystal structure near the surface of the coin. One possible explaination for this structure would be that the counterfeit was a cast button of brass with the surface design imparted by a pantograph or a similar machine. Another possible manufacturing route is again a cast button of brass lightly struck with dies produced by a pantograph or a similar machine. It should be noted that coin P7 shown on the left is a mule. The correct match for the 1994 obverse is the "Scotish Lion Rampant". No great numbers of this type have been found. The author has not seen a new example in the last four years. It is possible the counterfeiter has ceased production or changed the production process. |

5.0 Miscellaneous

This class is used for unusual production methods. Currently no counterfeits have been placed in this class.

References

Note 1: "Caution--forgers at large" by D.J.Cane, Coin News, February 2000, pp 29-30

Note 2: "The development of a classification system for modern UK £1 forgeries" by R.W.Matthews & G.Hughes, presentation at a Royal Numismatic Society -British Museum symposium on "Counterfeiting: ancient and modern", London 14-15th September 2000

Note 3: "Numismatic Forgery" by Charles M. Larson, pp 55-100, published by Zyrus Press, 2004, California